How to Make Wood Pellets: A Guide for Beginners

Making your own wood pellets can be an excellent way to cut costs and live in a more environmentally friendly house. There are many different ways to make pellets, but in this guide, we will focus on the most common method: using a pellet mill machine. Pellet mills use heat and pressure to create tiny pellets from biomass materials like wood chips or sawdust. Keep reading if you want to discover how to produce wood pellets!

What Are Wood Pellets and What Are They Used For?

Wood pellets are a type of fuel that is created from compressed sawdust or other types of wood waste. They can be used to generate electricity or heat homes as a sustainable, renewable energy source. Wood pellets are typically made from hardwood trees such as oak or maple, but they can also be made from softwood trees like pine. The pellets are formed by compressing the wood waste under high pressure and then sealing it in a moisture-resistant wrapping. This process helps to preserve the energy content of the pellets and makes them easier to store and transport.

Wood pellets are commonly used in pellet stoves or boilers, which are designed to burn the pellets to generate heat. Due to their higher efficiency and reduced emissions, pellet stoves are a well-liked substitute for conventional wood-burning stoves. In addition, wood pellets can also be used in large-scale power plants to generate electricity. When burned in a power plant, wood pellets release carbon dioxide and other greenhouse gases into the atmosphere. However, wood pellets are still considered to be a cleaner energy source than fossil fuels such as coal and natural gas.

How to Make Your Own Wood Pellets?

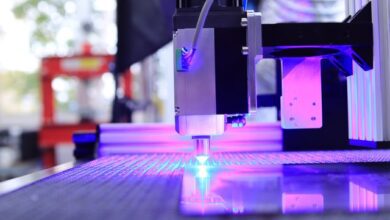

If you’re interested in making your own wood pellets, the process is actually quite straightforward. All you need is a pellet press, also known as a pellet mill machine. This type of machine compresses sawdust or other pulverized wood material into small pellets that can be used for fuel. Pellets made from hardwoods are especially popular for use in Pellet stoves, as they produce more heat than pellets made from softwoods.

To start making your own wood pellets, you will need:

- A Pellet press or Pellet mill machine

- Biomass materials like wood chips, sawdust, or leaves

- A source of power for the Pellet press (electricity or manual power)

- A container to collect the Pellets

The first step is to gather your biomass material and shred it into small pieces if necessary. The smaller the pieces, the better the compression in the Pellet press will be. If you are using a flat die Pellet press, you will need to place the biomass material into the hopper on top of the Pellet press. If you are using a ring die Pellet mill, the biomass material will need to be placed into a chamber below the Pellet mill. Once the chamber is full, it will need to be emptied before more biomass material can be added.

The next step is to select your Pellet size and set up your Pellet press accordingly. Once everything is set up, you can start Compressing the biomass material into pellets. It is important to keep an eye on the Pellet press during this process as overloaded presses can overheat and catch fire.

When the pellets are finished, they will need to be cooled before they can be used or stored. The cooling process can be done by spreading them out on a cooling rack or by placing them in a bucket of water. Wood pellets can be stored in airtight containers until they are ready to be used.

The Benefits of Using Wood Pellets

Wood pellets are arguably the most environmentally friendly type of fuel. This is because, unlike fossil fuels, they do not release any greenhouse gases when they are burnt. They also produce less soot and particulate matter pollution than other types of wood fuel, like wood logs or charcoal.

The list benefits of using wood pellets are:

- No exposure to black carbon, which is a negative externality of traditional cooking methods in developing countries and has major health impacts

- Wood pellets can be used with coal stoves so that people can still cook their food if they don’t have electricity. They emit less carbon dioxide than coal and they produce more heat per unit weight than coal

- Wood pellets are much easier to transport than wood logs, which means that they can be used in areas of the world with limited access to fuel or where there is a heavy reliance on wood for cooking.

Tips for Creating the Perfect Batch of Wood Pellets

The following pieces of advice from the article can aid one in creating their perfect batch.

1. Don’t Mix Different Types of Wood Together: The fuel inside your pellet stove relies on the chemical properties of wood to create heat instead of burning, which typically creates ash and cinders. Splitting or ring-sawing logs in different orientations of growth layers can also lead to splitting more easily.

2. Rotate Slow Burning Pieces Toward Center: Slow burning solid pieces with denser, less porous grain structures are harder to break up, once they’ve gone through a good drying cycle (e.g., Black Locust). Fattier pine will also be slower firing than spindly white pine switch wood within the pile when possible, especially among top layer wood storage in the dryer.

3. Use the Most Difficult Pieces First: Your stove should be able to maintain a steady fire on the first few pieces you light before you have to add more fuel into it, as they will tend to burn faster as they catch up with their counterparts.

4. Keep Your Fire in Context: A stove is not a space heater. It should only be used to provide heat in times of need and for those who have the means and the skills to build it.

5. Start Out Small: Know that it will take time for the fire to really get going, so start with a small-medium-sized piece of fuel before you get something large.

6. Build a Fire Pit: Keep your fire contained to where it’s needed, and build a fire pit to keep the flame from spreading into unwanted places.

7. Burns Out Fast: Don’t let a small fire burn out too quickly, because it will take time for it to start again and you might have to wait in cold weather.

8. Keep it Clean: Remove ash, coals, and rubble before you leave the site and dispose of it in an appropriate manner.

9. Let it Burn: A good fire will burn itself out if left unattended for too long, so don’t let that happen! Watch your fire to make sure it’s burning well and carefully remove hot embers before leaving the site.

Conclusion

Making your own wood pellets is a great way to reduce your carbon footprint and save money on your heating bill. With a little effort and some patience, you can create high-quality pellets that will be a source of fuel in your home and keep you warm all winter long!